Vision systems integrated into OFS

OFS integrates control systems by making them part of the process recipe and recording data on batches in transit.

In-line quality controls

The need for continuous control makes vision systems ideal for achieving a high production standard.

Active controls

Not only control but also removal of non-conforming products for automated quality control procedures.

Vision and control systems

In the quality control process, artificial vision has become a significant part.

Real-time measurements contribute to a significant increase in product standardisation.

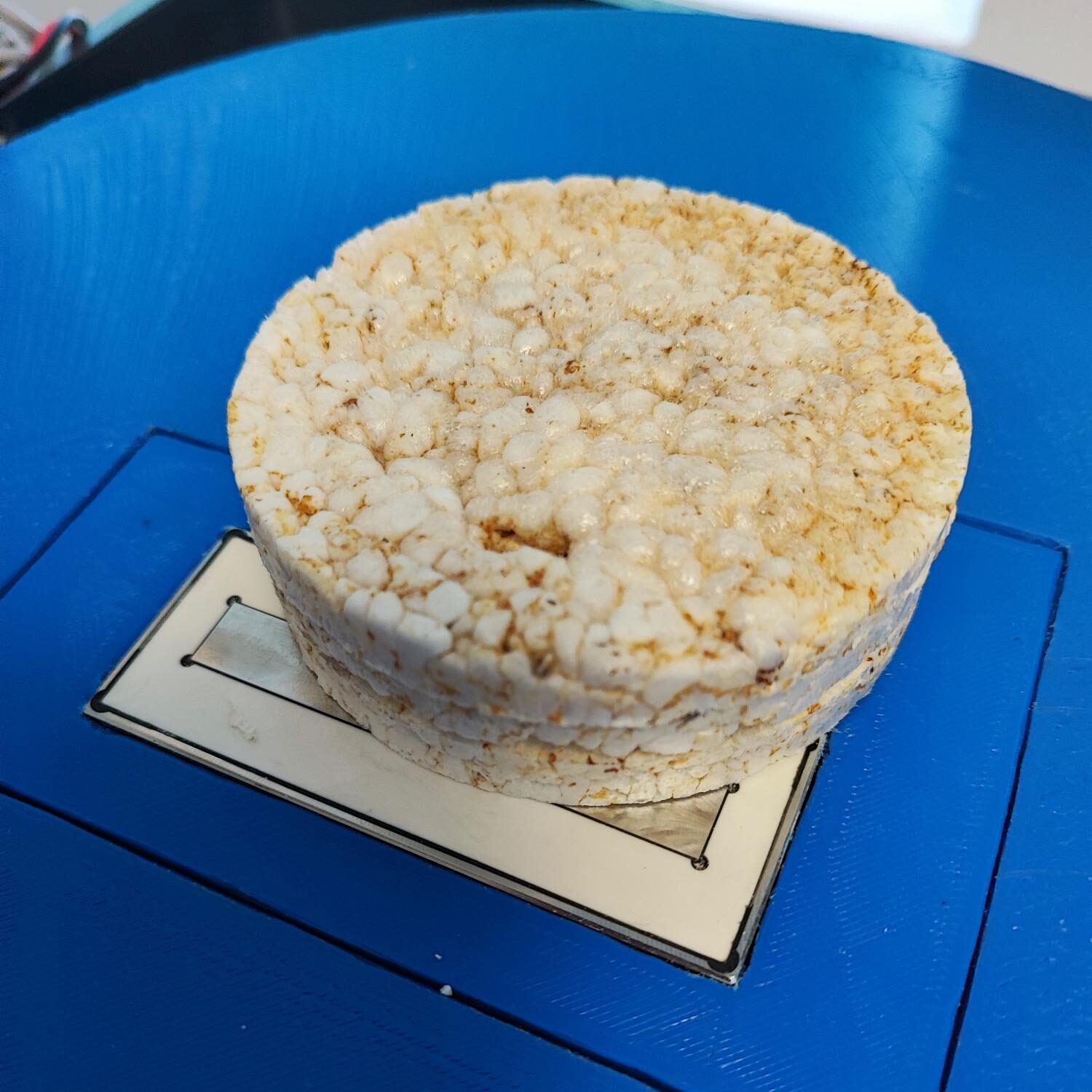

Laser technology

The use of laser ensures greater precision and allows the measurement of heights.

Vision tech applications in the food industry

Ovality and pizza dimension control

In-line camera for checking the minimum and maximum size and ovality of pizza.

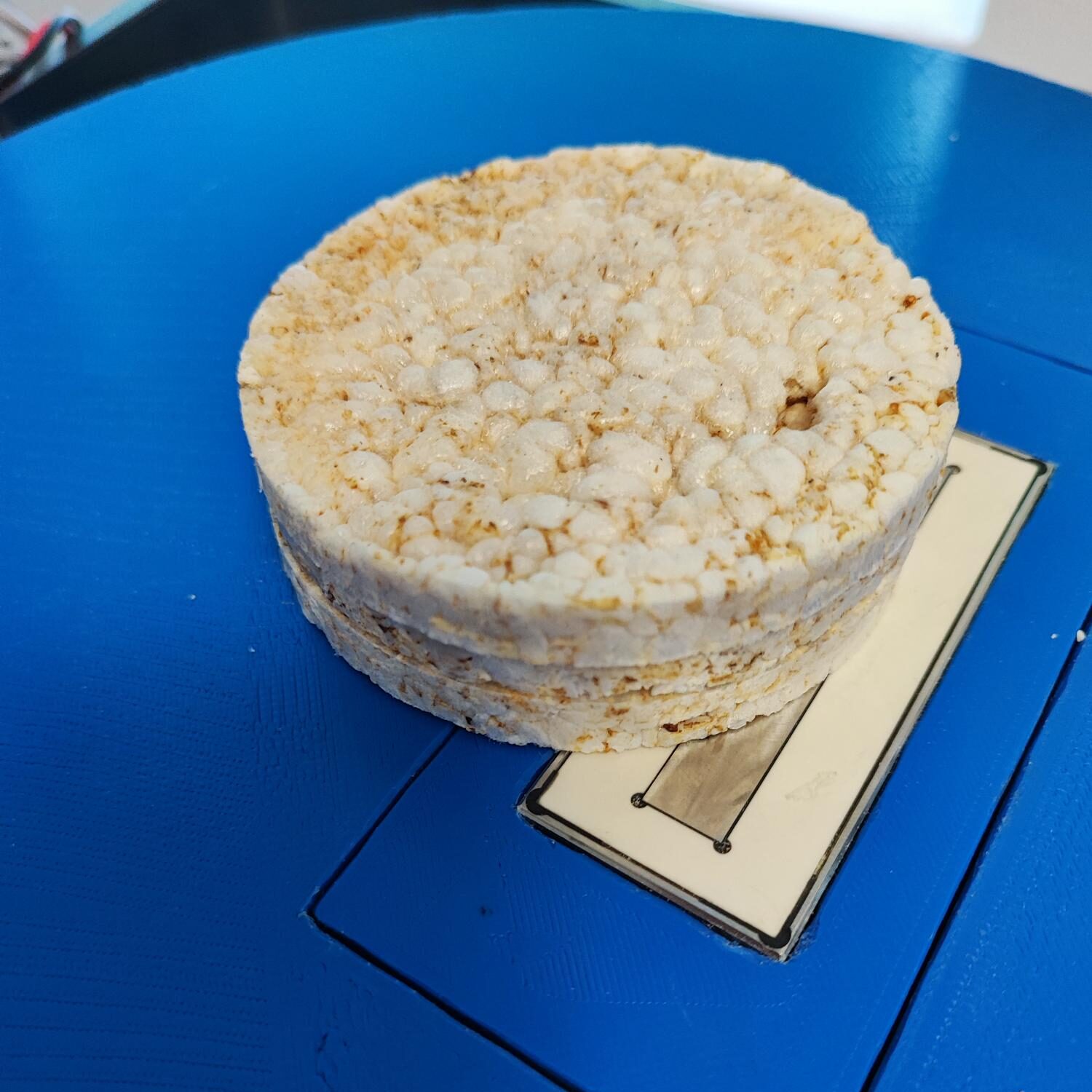

Piece counting and average product height measurement

Camera and laser for product height control and piece counter for loading semi-finished warehouses.

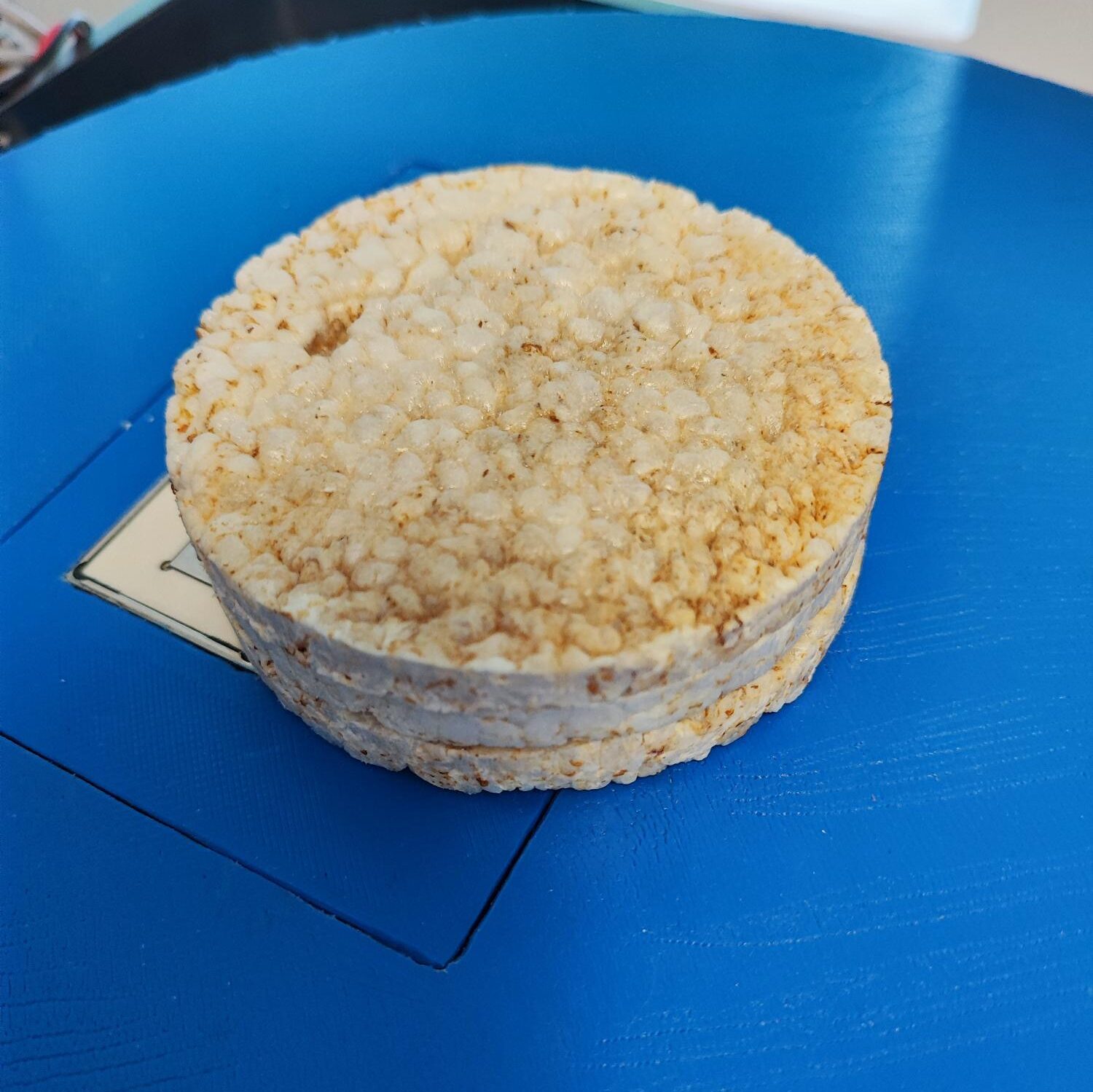

Photo acquisition for A.I

System for acquiring photos to be processed with artificial intelligence algorithms for optimal defect control.