Integrated quality control

Quality control integrated into OFS schedulable from product recipes.

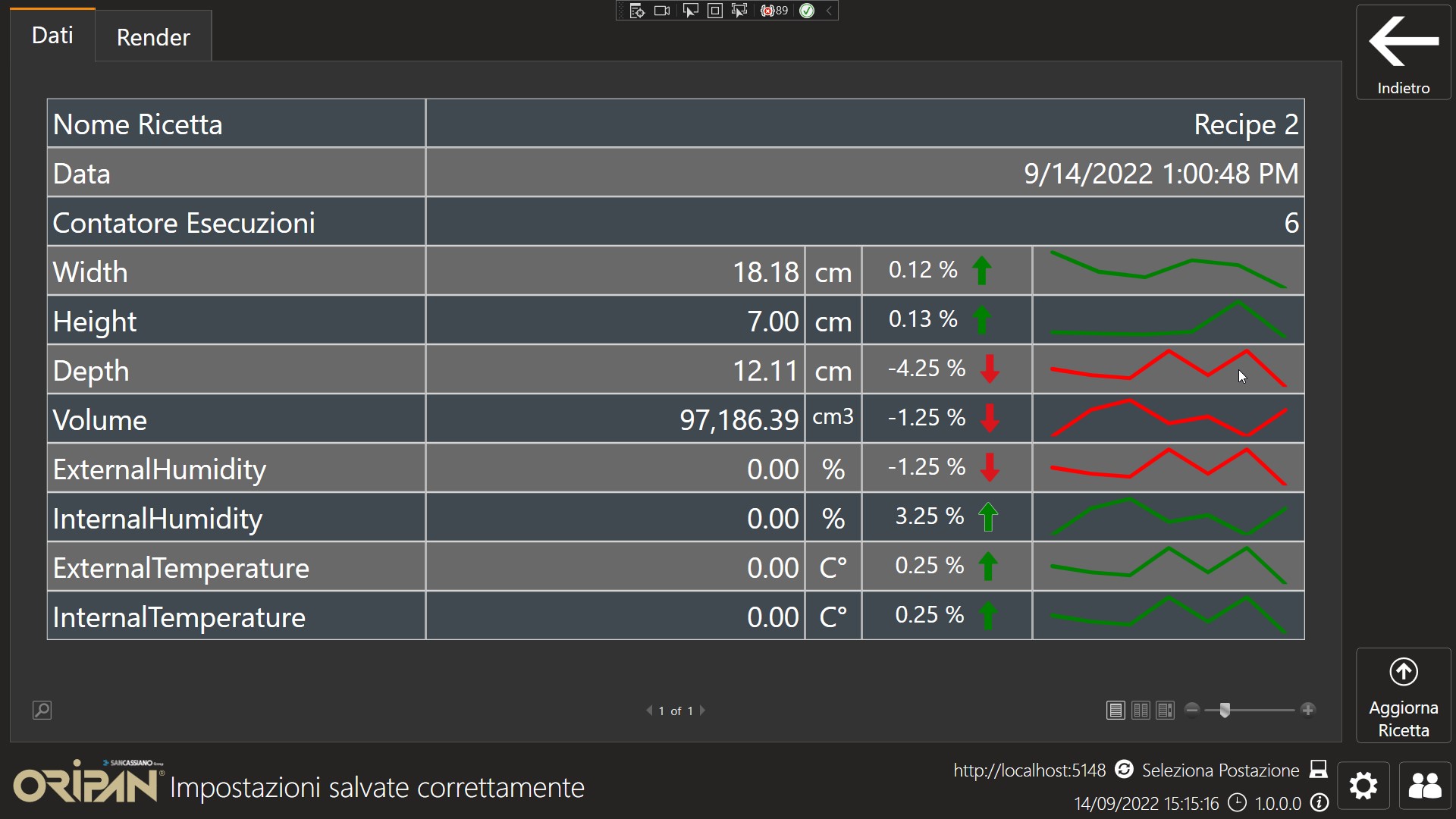

Physical measurements

An automatic procedure detects the physical dimensions of the product.

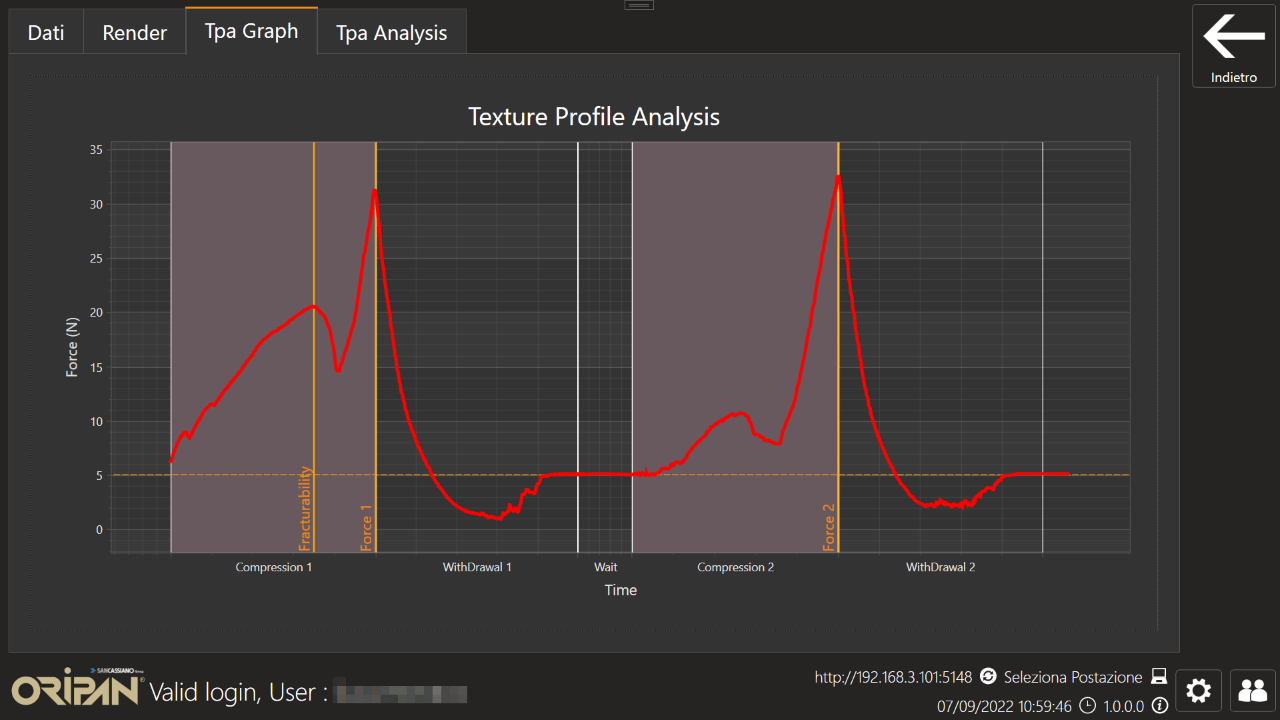

TPA analysis

Texture Profile Analysis provides an organoleptic fingerprint of the product and compares it with the stored setpoint.

A new concept!

Machine for quality control in production.

A real-time analysis procedure compares the measurements of the product under test with the relevant standard parameters in order to detect potential anomalies as early as possible and, if necessary, take the necessary actions to bring the system back to production within specifications.

Collected data

The machine automatically measures and obtains physical quantities of the product.

Physical measurements

They define the distance from the production standard…

Weight, volume, density and moisture are the main characteristics to control the standardisation of a leavened product. Core temperature, on the other hand, is crucial for optimal packaging.

TPA- Texture Profile Analysis

The machine automatically measures and calculates certain food sensory quantities.

Texture analyzer

TPA digitally defines food consistency…

Digitising the consistency of food and standardising its organoleptic characteristics such as stiffness, stickiness, elasticity, adhesiveness, etc. allows real-time corrections to be made to the product.

Typical perforation and compression curve – Semolina bread

Environmental measurments

Record of environmental measurements for each test cycle.

Environmental measures

They define the physical environmental quantities at the time of the test…

The quality of a product is also partly influenced by the temperature and humidity during production, making it essential to have these environmental quantities available.

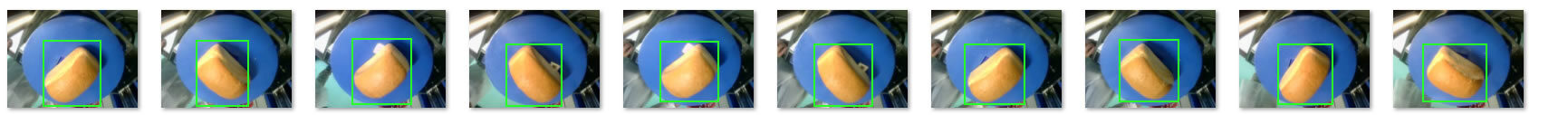

Photographic measurements

An automatic procedure photographs the product in different positions for a defect check using artificial intelligence.

The product is cataloged by name and lot and made available for color comparison and defects.